Have you ever driven a vehicle where the headlights were aimed poorly and you can barely see anything? Did you know that headlights aimed too low can reduce visibility just as badly as headlights aimed too high?

If your headlights are pointed at the ground it causes glare on the road which negatively affects your ability to see far down the road. If your headlights are aimed a little too high they could be shining into space reflecting off nothing rendering them practically useless!

Properly aiming your headlights is actually harder than you think – it’s downright scientific! If you’ve never measured your beam the correct way, chances are they are not aimed correctly, and they are out of alignment.

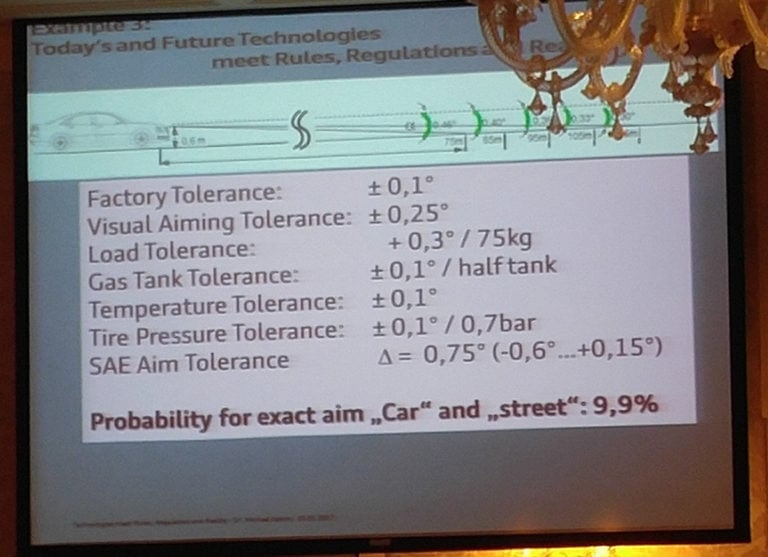

I recently attended the 2017 DVN (Driving Vision News) USA workshop in Detroit, MI. The central theme was “Future Lighting Technologies and Standardization, Safety and regulatory Affairs”. One of the discussions presented was an argument about how difficult it is to keep headlights aimed properly, and how that relates to regulatory guidelines.

9.9% of the time headlights are misaimed causing 3% – 30% more glare than they should.

Hassan Koulouh of AML Systems showed calculations from research and survey data that proved nearly 10% of the time any vehicle is on the road the headlights are misaimed causing between 3% – 30% more glare than what is allowed for by NHTSA aiming regulations and IIHS guidelines. The surprising thing is that a lot of time this misaim has a lot to do with physically incorrectly aimed adjustment mechanism on the vehicle, but the rest of the time headlight misaim comes from:

- Luggage in the trunk

- Heat of the headlight lens from the light being on

- Gas tank fuel level weight

- Issues with the flatness of the road

- Tire pressure

- And of course the mechanical aim of the actual headlight housing by the driver or technician

Koulouh works for a company called AML Systems, owned by Johnson Electric, that manufacturers and supplies a new headlight aiming technology called LuMEMS – Auto leveling using MEMS sensors. They claim that the further use of their intelligent actuator system in more vehicles will eliminate most if not all issues that cause headlight misaim. If we could solve headlight misaim there would be a reduction in nighttime driving accidents, eye fatigue, and oncoming driver glare.

“We have to adjust the speed of regulation to the reality of what’s happening. as the OE market demands LED, and ADB, and the aftermarket demands new types of bulbs, regulation will be forced to comply…” – Hassan Koulouh, Head of Innovation Lighting Segment at AML Systems

The interesting thing about current regulation and safety ratings is that they rate the beam pattern and headlamp aiming result, not anything to do with the actual headlight. Therefore a higher value vehicle does not automatically guarantee you better lighting on the road. The same is said for the type of headlight: halogen incandescent, HID, HIR, or LED. If more vehicles came equipped from the factory with an automatic and intuitive adjustment system like the LuMEMS product there would be fewer misaimed headlights driving down the road and that would be better for everybody.

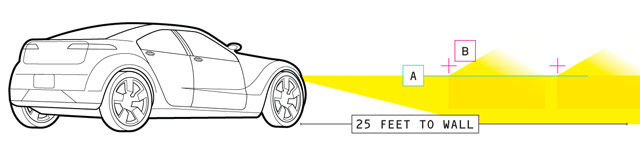

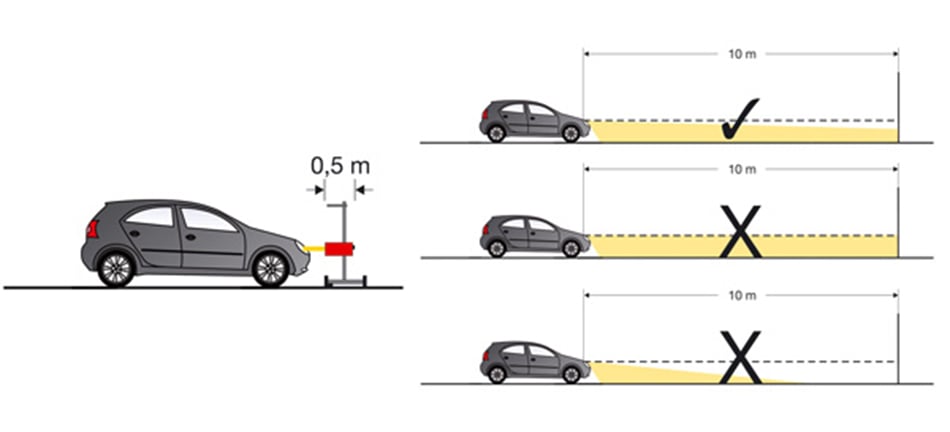

Did you know that with as little misaim as 0.2 to 0.5 degrees a properly aimed headlight can become a misaimed beam pattern? Something like that could be caused simply by too much luggage in the back of your vehicle or installing replacement light bulbs because one burnt out. Given the exponential degree of change the further away from the front of the vehicle you measure, if your headlights are misaimed by just half a degree, your down-range usable light around even 75 feet ahead could be compromised and potentially useless.

If you don’t know the steps on how to aim your headlights, read this first and go aim your headlights! If you’re part of the OEM community in manufacturing parts or vehicles, please do us all a favor and push for further integration of auto-leveling headlight systems!

.png?width=300&height=87&name=logo%20(1).png)