If you’re on vacation and the back of the car is loaded with hunting and fishing gear, maybe even a large catch, plus other “road hugging weight,” that’s probably the cause of your headlight problems. Same goes for if you’re pulling a trailer with your truck forcing the front end to rise into the air like a one-sided teeter totter… That extra weight pushes down the rear enough to tilt up the front and the beams. If you periodically carry heavy rear-end loads as part of your lifestyle, the only real cure is a pair of load-leveling air shocks.

If your truck looks like this when pulling a trailer you need a bigger truck or air shocks… Headlight misaim is the least of your problems!

However, in most cases, the headlamp aim has gone off and simply needs readjustment. Why? Replacing the front headlamp assembly certainly could do it—a stack-up in manufacturing tolerances could affect the way the assembly seats. Even a new halogen bulb might be responsible, although that’s less likely. Things as normal as luggage in the trunk, the amount of fuel in your gas tank, tire pressure, and suspension setup could all cause an issue in the headlight aiming department.

And headlamp aim doesn’t last forever, particularly if the assembly loosens and shifts or if the vehicle’s suspension sags.

Many models (particularly Hondas and Acuras) have a bubble level in the headlamp assembly to check vertical aim. This does make it easier to diagnose unwanted tilt. Just make sure the tire pressures are at specs and the vehicle is on level ground (check with a carpenter’s bubble level on a flat surface). Have the fuel tank half-full and someone in the driver’s seat. Reposition the car if necessary to get a level location. Jounce each side of the front end of the car up and down a few times to settle the suspension. Measure from any convenient fixed point on each of the headlamps to the ground; the measurements should be within 1/2 in., indicating the suspension is not sagging excessively at either side. Then, locate the vertical adjuster and turn it to center the bubble.

Even if your headlamps have a bubble level, it’s strictly for vertical aim. It’s less common, but still possible, for the headlamp aims to be off horizontally. The left headlamp may be aimed at the oncoming cars instead of straight ahead or slightly to the right, and that’s equally annoying. But you might be in luck. Some cars with a bubble level for vertical aim also have an alignment indicator for horizontal aim (here again, Honda and Acura). You just have to turn the adjuster to reset the indicator.

On most vehicles, however, it isn’t quite that simple because there is no bubble level or horizontal alignment indicator. All you have are the adjusters, and in some cars, only for vertical aim. If the horizontal aim is off and there is no horizontal adjuster, the issue is the mechanical alignment of the housing in the front end, and all you can do for this is shim one side of the housing—it’s a cut-and-try operation—until the alignment of the beam is acceptable.

Without indicators in the housing or professional headlamp alignment equipment, you have to look at how the beams strike a vertical flat surface, and if they’re off, make adjustments.

Properly aiming your headlights is actually harder than you think – it’s downright scientific! If you’ve never measured your beam the correct way, chances are they are not aimed correctly, and they are out of alignment.

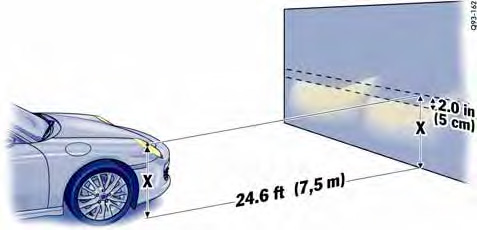

Proper headlight aim is critical. Check aim with a driver in the car and a full tank of gas. The low-beam cutoff (a) should be slightly below the center of the lens (b) to keep the glare out of oncoming traffic and reduce the light reflection that occurs during rainy or snowy weather. The bend in the cutoff should be slight to the right of the center of the lane, for the same purpose. This will illuminate the road surface in front of the car, as well as the curb area to the right.

There is a standard procedure, using a flat and level driveway facing a gray or dull white wall that is free of any source of peripheral light (perhaps the back wall of your garage, interior lights off). The open space on the wall should be at least the width of the vehicle plus an extra 2 ft. per side. Check the tire pressures—they have to be right.

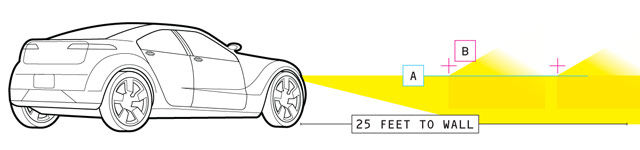

- Confirm that the car is on level ground by using a good carpenter’s level on the side of the vehicle—on an SUV try the roof, and on most cars, the door frame. Park the car so it’s exactly 25 ft. from the wall to the face of the headlamps—don’t estimate. Some exceptions include Toyota, which specifies 10 ft., Pontiac GTO at 15 ft., and Chrysler, which specifies 33 ft. on some models. However, the 25-ft. procedure should produce satisfactory results for most vehicles. Use a tape measure in any case.

- Check the suspension ride height side to side to make sure there’s no excessive suspension sag.

- Now comes a lot of very careful measuring. First, identify the physical center of each low-beam headlamp—with today’s multi-lamp housings, actually turn on the lamps to be sure you have the right lamp. Some headlamps have a small dot or circle at the center. Make a tape cross over the center of each lamp, and a vertical tape line down the center of the windshield. Using a tape measure, make the corresponding alignment marks on the wall.

- For this part, you might be able to measure at the wall from the ground up, but it’s easier (and good for a double-check) to bring the vehicle very close to the wall. Then, again with tape, transfer the locations to the wall (perhaps using a bubble level to span the gap between vehicle and wall, to ensure an accurate transfer). On the wall, make the tape lines very wide—basically a single horizontal line for both centerlines of the headlamps, and a vertical tape line for the centerline of the vehicle—and long enough so that it’s easy to line up the vehicle and for the lines to form a cross. Make the centerline vertical crossing tapes for the headlamps themselves about 2 ft. long on the wall. The accuracy of any adjustment is only as good as the reference points. In fact, it’s a good idea to lay strips of tape on the ground at the midpoints of the rear tires, so that when you back up to the specified distance from the wall, you can be sure you’ve maintained the overall alignment of the vehicle to the wall. The tape on the windshield and the centerline of the wall also should be useful visual aids.

- Next, locate the headlamp adjusters. If you’re a veteran Saturday mechanic, this may sound like “are you kidding,” but we’re serious. The adjusters used to be on the external rim of the sealed-beam headlamp assemblies. But with the change to quartz halogen bulbs, they’re on the back of the headlamp assemblies. Some makers simply buried or eliminated the horizontal adjusters. To find out what you have, and where it is.

We’ve seen a number of “mainstream” cars (yes, that includes General Motors) with the vertical adjusters at the bottom of the housings. It’s not a problem if there’s nothing in the way of the adjuster, but we’ve seen the battery, coolant reservoir, even the antilock brake actuator behind it. You may have to remove what’s behind the housing to confirm the location of the adjusters, or even to be able to put a tool on the adjuster.

Once you locate the adjusters, back the vehicle up to the 25-ft. mark and turn on the low beams—do this on a dark night. Have a passenger sit in the driver’s seat. Block the light from one headlamp, but not by covering the headlamp assembly (it could get hot enough to melt the plastic lens). A kitchen chair with your jacket draped over the back a couple of feet from the bumper works well. - Look at the light pattern on the wall. Vertical aim: The top of the most intense part of the beam should be at or below the centerline of the headlamp horizontal tape line. Horizontal aim: Most of the intense part of the beam should be to the right of the vertical centerline of the headlamp assembly.

Specifications vary, and if your state inspection system checks headlamp aim, it may have its own specifications, which, of course, you should use. Otherwise, observe the manufacturer’s specifications (in the lighting sections of service manuals) if available. With today’s brighter headlamps, you want to be as friendly as possible to oncoming cars without affecting your ability to see ahead.

Some examples of factory specifications on typical vehicles (measured below the horizontal centerline of the headlamp): zero distance on General Motors, less than 1/2 in. on Toyota (at the 10-ft. distance), less than 1 in. to slightly more than 3-1/2 in. on Nissan vehicles, and 2 to 6 in. on Chrysler Group vehicles. If you don’t have specifications (or a bubble level in the assembly), at least 2 to 4 in. below the centerline at 25 ft. should be acceptable, although slightly more certainly would eliminate any complaints from oncoming vehicles. It may be somewhat difficult to determine the middle of the most intense part of the beam, but there should be very little of the top edge of the overall beam above the horizontal line. The “kickup” is the part of the pattern where light is projected above the normal cutoff. This is to illuminate objects to the right, such as road signs or pedestrians, without throwing glare onto oncoming traffic.

Have to make adjustments? First jounce each side of the front end to stabilize the suspension, then turn the adjuster a quarter-turn and look. The horizontal aim of the most intense part of the beam may be given in the manufacturer’s specifications. If not, a friendly setting for oncoming cars is 2 to 4 in. to the right of the vertical center of the headlamp assembly.

General Motors’ ultra-friendly setting is to have the left edge of the intense part of each beam flush with the physical vertical centerlines of the headlamp assemblies and just under the horizontal centerline. Repeat the procedure for the other headlamp, trying to get the most intense part of the beam as close to the adjustment of the first headlamp as possible.

.png?width=300&height=87&name=logo%20(1).png)