Why are they the best? Here's one reason:

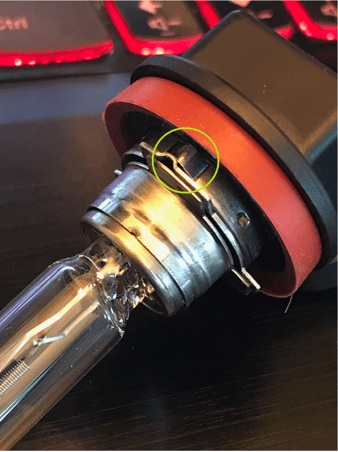

They go the extra mile by adding OEM style components to their aftermarket bulbs to ensure the best fit and alignment. Have you heard of a Tension spring? Most haven't, and that's a problem!

Morimoto proves itself again to be the benchmark in automotive lighting with the 2stroke 3.0 H11 bulb release. Today, we will be breaking down the H11 bulb, and what sets this product apart from others like it on the market.

The H11/H8/H9 Base

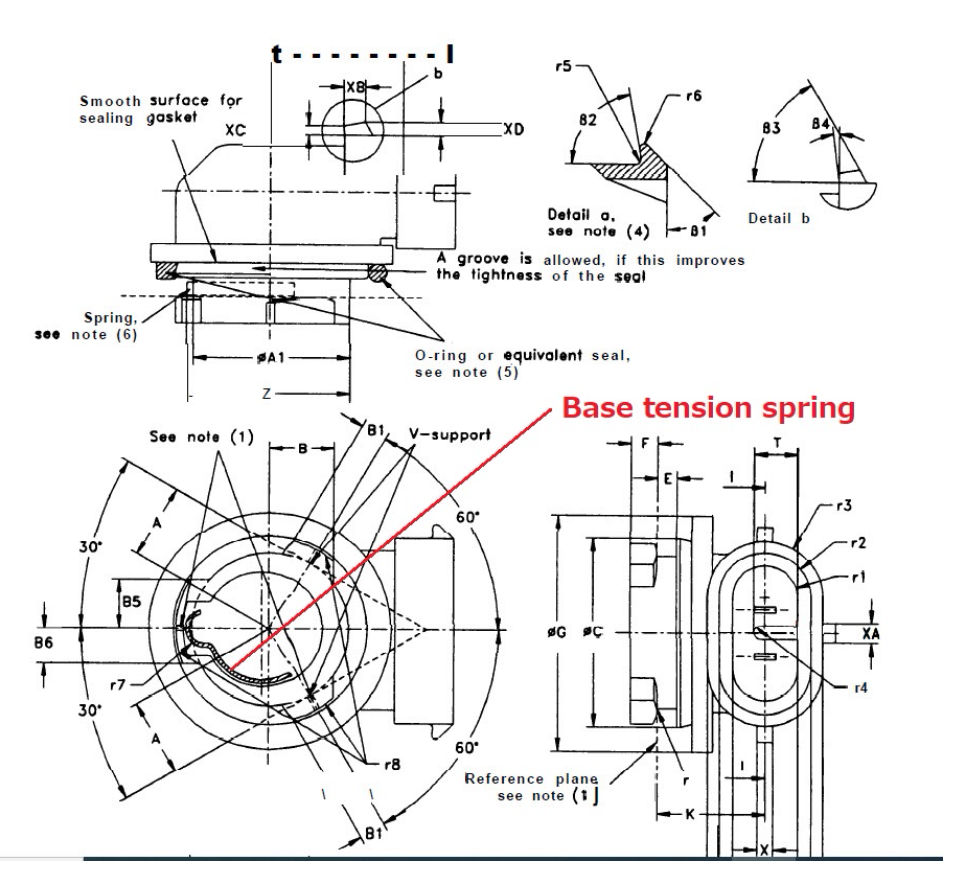

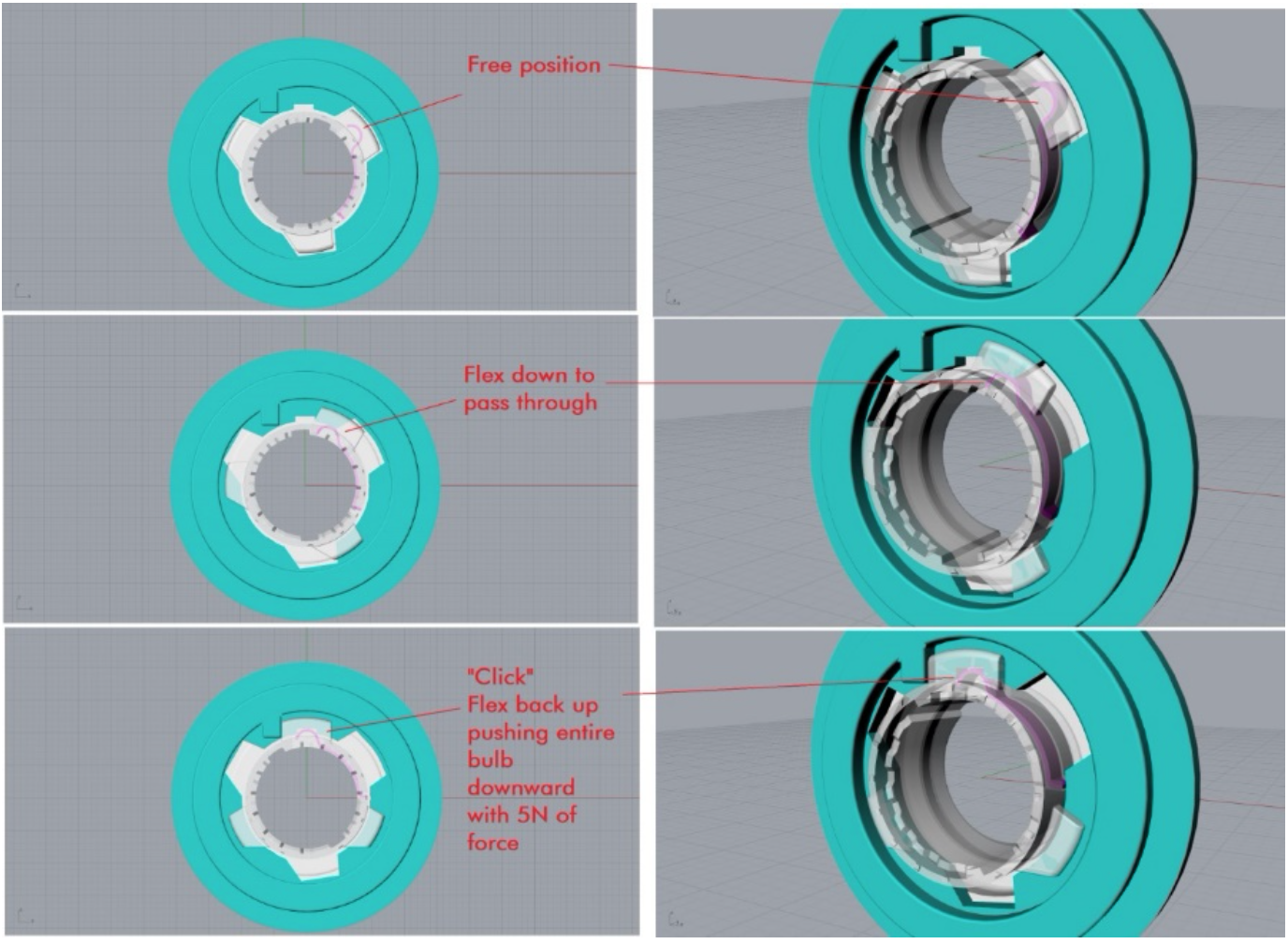

The Halogen H11 (also applies to H8, H9, and H16) base has a base tension spring that creates 5N of force once installed (10N of force during the insertion process).

This level of force ensures the H11 bulb seats correctly within the headlight housing and locks in place. The H11 bulb requires a slightly larger opening to pass through due to the tension spring. The larger space also allows for room to align the bulb axis correctly.

The base tension spring also plays a vital role in assisting the proper alignment of the bulb axis by locking the bulb in place.

The Competition

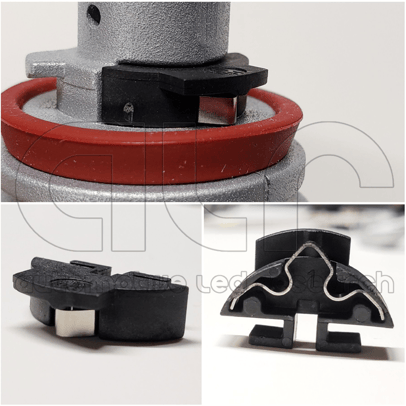

Our research only found one other example of this technology within the industry, the Osram H11 fog lamp bulb.

While this significantly contributed to the LED bulb market, Osram's bulb base has ridges along the LED bulb body, making it difficult for the bulb base to rotate for proper installation.

(Photo courtesy of Automotive LED Research)

(Photo courtesy of Automotive LED Research)

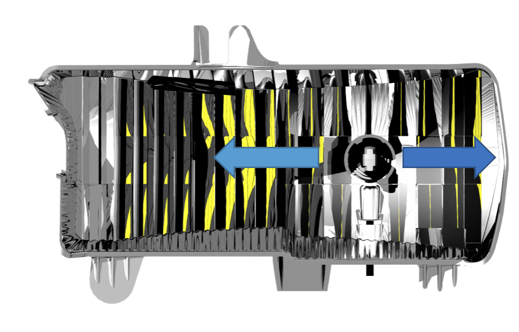

The LED bulb has a limited, selective illumination range due to LED being a surface lighting device. If the design has 2 LEDs face out, it can achieve the optimum/desired rotational angle.

Why this Matters in Reflector Headlight Housings

The vast majority of reflector housings have an overall horizontally longer fixture design. The outer segment of the reflector carries critical beam center intensity and cut-off definition.

The challenge becomes that there aren't many headlight housings designed for the H11 halogen bulb to be inserted at that angle. This isn't the case with halogen housing since the halogen bulb is a cylindrical filament light source. Halogen can emit light at 360-degrees, but with a limited illumination range. This limitation results in the LED chip not facing the optimum rotational angle.

For this type of housing, insert the bulb at a 120-degree angle (see above image). Once the bulb base is locked in place, the LED will be pointing at 4 and 10 o'clock, which compromises the performance. The ideal placement is so that the 2 LED chips are pointing in the 3 and 9 o'clock directions.

Solution to Bulb Base Rotation

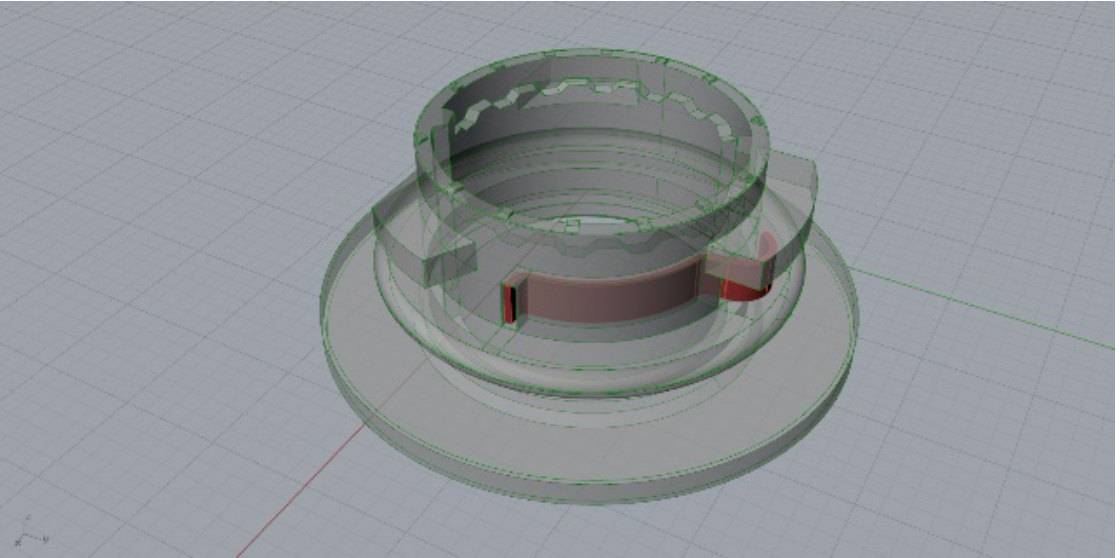

Numerous LED bulbs have rotatable bulb bases called "clockable bases." Putting it simply, the word "clockable" means the design allows the base to rotate around the LED bulb.

(Market sample Ultra 2.0 H11)

(2Stroke 3.0 H11 Model)

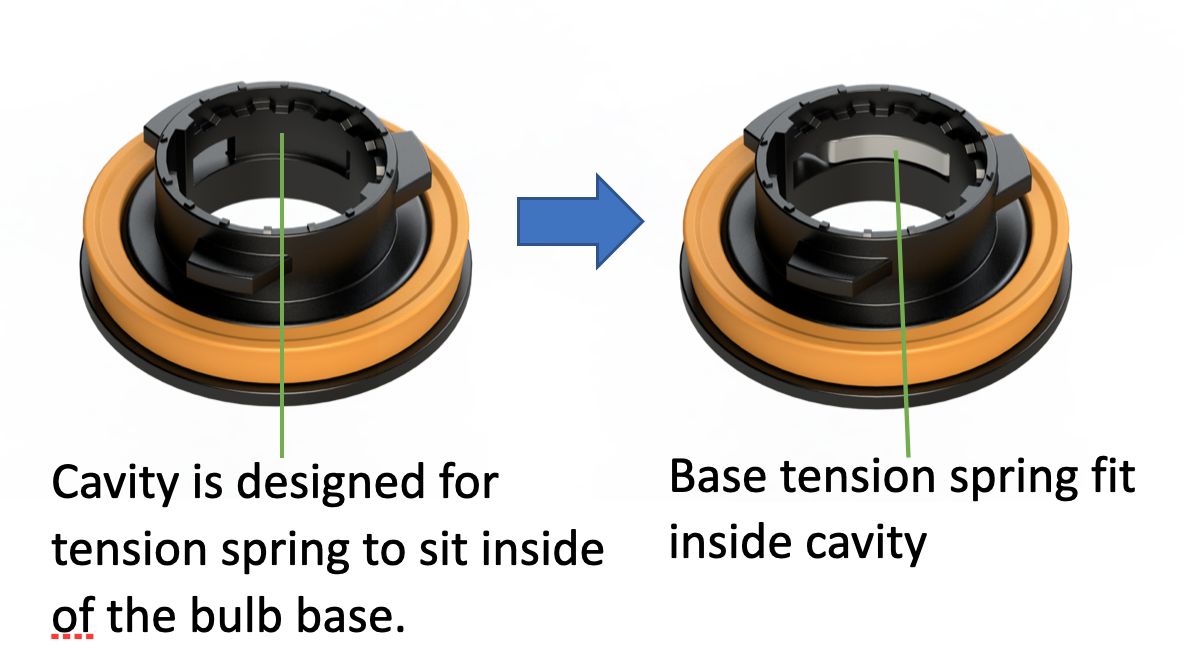

What makes the 2stroke 3.0's H11 bulb base exceptional is its rotatable H11 bulb base with a tension spring. No other LED bulb on the market has this.

The tension spring sandwiches itself between the bulb base cavity and the LED bulb front shaft portion to ensure the bulb is locked in place.

Overall, this bulb sets itself apart with the locking tension spring and rotatable bulb base, ensuring any headlight bulb adjustment will stay in place for accurate beam pattern and optimum visibility.

No more having to readjust over and over again. Just set it, lock it and go drive.

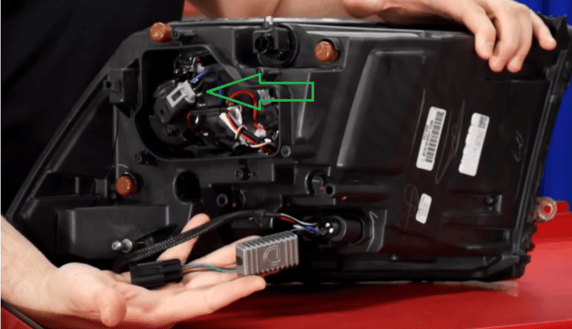

To learn even more about this bulb and what makes it so special, you can watch the review done by The Retrofit Source where they cover this incredible technology on display:

Skip to the 6:22 mark in the video to learn more about the tension clip built into the bulb!

.png?width=300&height=87&name=logo%20(1).png)