IMPORTANT TECHNICAL BULLETIN

In the HID conversion kit system there are three main components: The ballast, the adapter wiring, and the bulb. When one of these components fails it has the potential to damage the other components at that time.

1. Mounting the ballast:

When mounting the HID ballast, keep these things in mind:

Always use the supplied bracket if available. Never mount where the ballast will be exposed to the elements, and never mount the ballast with double sided tape! Always try to mount the ballast to a metal structure to promote heat dissipation. When using double sided tape to mount your ballast the tape acts as an insulator from the metal that the ballast should be mounted to, which creates an opportunity for the ballast to overheat.

The GTR Lighting GEN 3 CANBUS Pro 35w HID ballast is arguably one of the best HID ballast options money can buy.

2. Clean the bulbs:

When installing HID bulbs, even when they are brand new, clean them with isopropyl alcohol and allow them to air dry before installing in the housing. This ensures there are no contaminants on the bulb that will cause premature failure. When a bulb fails it may damage the ballast that was powering it.

Also it is important that the housing the HID bulb is being installed into is sealed so it cannot be contaminated from the outside elements. If your housing is open when the bulb gets wet and dirty it can fail the next time it is turned on.

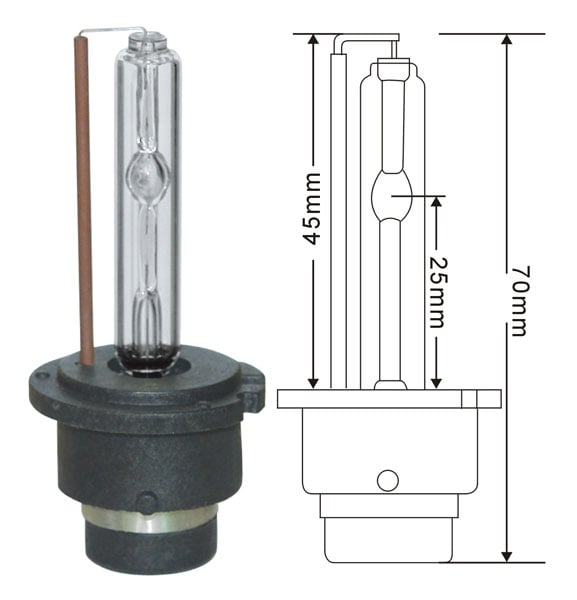

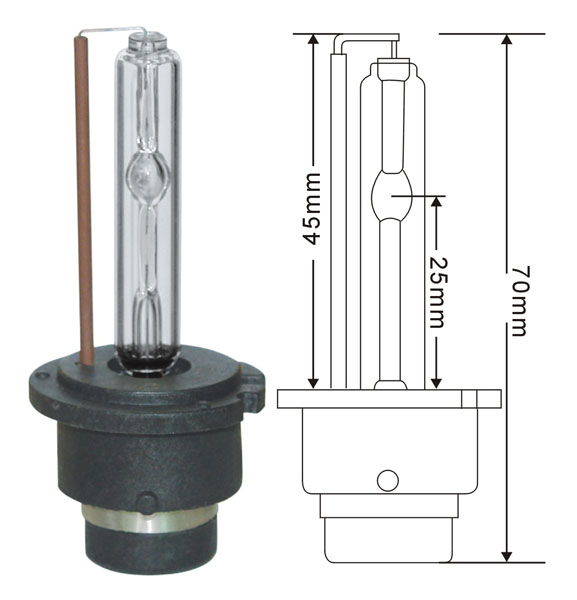

The GTR Lighting Ceramic-Base HID bulbs are the highest quality HID bulb available.

3. Use dielectric grease in your connections:

It is a good idea to use electrical-component-safe dielectric grease whenever a connection is made from the ballast to the bulb, or the power wire to the ballast. This promotes a good seal on the connection and will deter corrosion from forming on the electrical contacts.

The GTR Lighting HID relay harness is easily the most high-tech and reliable wiring accessory for your HID kit.

4. Turn the Auto-Headlight mode OFF:

Many vehicles have “automatic headlights” that will turn the headlights on during the cranking process when starting. When cranking the vehicle the current draw of the starter motor causes the whole electrical system to suffer from a low voltage condition that will send the HID ballast into a power protect mode, or cause the ballast to flash between spikes of available current.

If you see the HID lights flickering during startup, it is an indicator that you are damaging the HID system every time you turn the vehicle on. It may be necessary to disable the auto-headlight system, create a starter triggered relay to interrupt the power to the HID system during cranking, or wire the ballast power directly to the battery with a relay bypass harness.

5. Solve loose connections:

If your HID system wiring has any loose connections it will cause premature failure of the ballast, bulb or both. Intermittent connections will force the system to turn on and off frequently which is hard on the electronics.

.png?width=300&height=87&name=logo%20(1).png)